Production process and development of salted egg production products

Main Article Content

Abstract

Salted eggs are commonly eaten as a meal, especially with boiled rice or congee. Salted egg yolks may also be used as an ingredient in baked goods and bakery products such as mooncakes or spring rolls. Salting is a method used to produce salted eggs. In general, the qualities of salted eggs depend on the concentration of the brine, salting time, salting method and osmotic agents in salting solution. Therefore, data collection related to salted egg production methods as well as developing the production process for purposes such as reducing production time, lowering production cost, decreasing the loss of egg whites, producing low-sodium or salt in the salted eggs for consumers to decrease risk of developing kidney disease and adding biological agents that inhibit the growth of microorganisms, etc. Salted can be produced by the traditional pickling where fresh whole eggs are pickled in brine solution. Moreover, the yolks are pickled directly in normal salting solution containing osmotic agents to increase the efficiency of osmotic water removal and shorten the pickling time. These affect the physical and chemical qualities of the salted eggs. The salted egg produced has changed the chemical composition, including physical and chemical qualities that clearly affects the texture. This information can be used to further develop salted egg products according to the needs of different groups of consumers by controlling various factors related to salted egg production in order to reduce the time and cost of producing salted eggs with the desired qualities.

Article Details

References

กาญจนิจ กณิถอนันต์. (2515). การหาเปอร์เซ็นต์เกลือในไข่ดองเค็ม. [ปัญหาพิเศษปริญญาโท]. มหาวิทยาลัยเกษตรศาสตร์.

ศูนย์วิทยาศาสตร์และวัฒนธรรมเพื่อการศึกษาร้อยเอ็ด. (2564, 30 มกราคม). กล่องความรู้ สะเต็มศึกษาสู่อาชีพ เรื่อง การย่นระยะการดองไข่เค็ม. หน้า 6. https://pubhtml5.com/qwis/fwwt/basic

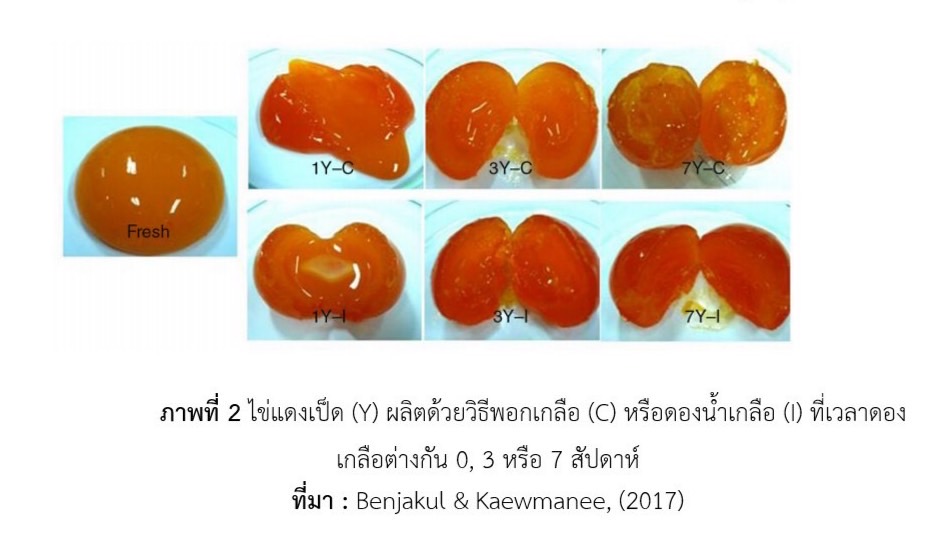

Benjakul, S. and Kaewmanee, T. (2017). Chapter 39: Sodium Chloride Preservation in Duck Eggs. In: Patricia Hester, editors: Egg Innovation and Strategies for Improvement, Oxford: Academic Press; 2017, pp. 415-426. https://doi.org/10.1016/B978-0-12-800879-9.00039-1

Chen, X.D., Y. Freeman, F. Guo & P. Chen. (1999). Diffusion of sodium chloride through chicken eggshell in relation to an ancient method of egg preservation. Food Bioproducts Process, 77(C1), 40-46. https://doi.org/10.1205/096030899532240

Chi, S-P. & Tseng, K. H. (1998). Physicochemical properties of salted pickled yolks from duck and chicken eggs. Journal of Food Science, 63(1), 27-30. https://doi.org/10.1111/j.1365-2621.1998.tb15668.x

Davidson, P.M., (2001). Chemical preservatives and natural antimicrobial compounds. In: Doyle, M.P.,

Beauchat, L.R., Montville, T.J. (Eds.), Food Microbiology: Fundamentals and Frontiers. DC: ASM Press, Washington, D.C., United States, pp. 117–126.

Foegeding, E.A., Davis, J.P., Doucet, D., & McGuffey, M.K. (2001). Advances in modifying and understanding whey protein functionality. Trends in Food Science & Technology, 13, 151–159. https://doi.org/10.1016/S0924-2244(02)00111-5

Harrison, L.J., & Cunningham, F.E., (1986). Influence of frozen storage time on properties of salted yolk and its functionality in mayonnaise. Journal of Food Quality, 9, 167–174. https://doi.org/10.1111/j.1745-4557.1986.tb00786.x

Harlina, P. W., Hu, M. M., Legowo, A. M., & Pramono, Y. B. (2012). The effect of supplementation garlic oil as an antibacterial activity and salting time on the characteristics of salted egg. Jurnal Aplikasi Teknologi Pangan, 1(4).

Kaewmanee, T., Benjakul, S., & Visessanguan, W. (2011). Effect of NaCl on thermal aggregation of egg white proteins from duck egg. Food Chemistry. 125(2), 706–712. https://doi.org/10.1016/j.foodchem.2010.09.072

Kaewmanee, T., Benjakul, S., Visessanguan, W. and Gamonpilas, C. (2013). Effect of sodium chloride and osmotic dehydration on viscoelastic properties and thermal-induced transitions of duck egg yolk. Food and Bioprocess Technology, 6, 367-376. https://doi.org/10.1007/s11947-011-0667-7

Kaewmanee, T., Benjakula, S. & Visessanguan, W. (2009). Effect of salting processes on chemical composition, textural properties and microstructure of duck egg. Journal of science food agriculture, 89, 625–633. https://doi.org/10.1111/j.1750-3841.2010.01975.x

Kiosseoglou, V.D. (2003). Egg yolk protein gels and emulsions. Current Opinion in Colloid & Interface Science, 8, 356–370. https://doi.org/10.1016/S1359-0294(03)00094-3

Kiosseoglou, V.D., & Sherman, P. (1983). The rheological conditions associated with judgment of pourability and spreadability of salad dressing. Journal of Texture Studies, 14, 277–282. https://doi.org/10.1111/j.1745-4603.1983.tb00350.x

Kunkriangwong, J., Tuitemwong, P., Saengdarerat, R., Phattarapanyakul, W., Kansup, W., Suntornsuk, W., (2002). Production of salty eggs using hydrostatic pressure. The Proceedings of 40th Kasetsart University Annual Conference. Kasetsart University, Bangkok, Thailand, 4–7 February 2002.

Lai, K.-M., Chi, S.-P., & Ko, W.-C. (1999). Changes in yolk states of duck egg during long-term brining. Journal of Agricultural and Food Chemistry. 47(2), 733–736. https://doi.org/10.1021/jf980486r

Lian, Z., Qiao, L., Zhu, G., Deng, Y., Qian, B., Yue, G., Zhao, Y., (2014). Use of sodium dodecyl sulfate pretreatment and 2-stage curing for improved quality of salted duck eggs. Journal of Food Science, 79, 354–361. https://doi.org/10.1111/1750-3841.12361

Novia, D., Melia, S., & Juliyarsi, I. (2014). Utilization of ash in the salting process on mineral content raw salted eggs. Asian Journal of Poultry Science. 8, 1–8. https://doi.org/10.3923/ajpsaj.2014.1.8

Puppo, M.C., & Anon, M.C. (1999). Soybean protein dispersions at acid pH: thermal and rheological properties. Journal of Food Science, 64, 50–56. https://doi.org/10.1111/j.1365-2621.1999.tb09859.x

Saeaung, W., Laoharatanahirun, A., Boonyaprapasorn, A. & Thipayarat, A. (2010). Novel processing of salted yolk production using separated yolk brining methodology. Food Innovation Asia Conference: Indigenous Food Research and Development to Global Market, June 17–18, BITEC, Bangkok, Thailand.

Shiquan, W., Shucai, W., Yipeng, Z., & Rong, Z. (2013). Parameter optimization for quickly salted egg by using ultrasonic–pulsed pressure technology. Transactions of the Chinese Society of Agricultural Engineering, 29, 286–292. https://doi.org/10.3969/j.issn.1002-6819.2013.23.039

Wang, C.T. (1991). The physical-chemical properties of salted egg yolk during granulation or gelation process. Journal of the Chinese Chemical Society, 29, 406-414.

Wang, T.-H. (2017). Salting yolks directly using fresh duck egg yolks with salt and maltodextrin. Japan Poultry Science Association. 54(1), 97-102. https://doi.org/10.2141/jpsa.0160027

Wang, X., Gao, Z., Xiao, H., Wang, Y., & Bai, J. (2013). Enhanced mass transfer of osmotic dehydration and changes in microstructure of pickled salted egg under pulsed pressure. Journal of Food Engineering, 117(1), 141–150. https://doi.org/10.1016/j.jfoodeng.2013.02.013

Yang, S.C., & Chen, K.N. (2001). The oxidation of cholesterol in the yolk of selective traditional Chinese egg products. Poultry Science, 80(3), 370–375. https://doi.org/10.1093/ps/80.3.370

Yimtoe, S., Haruthaithanasan, Y., Rimkeeree, H. (2001). Development of low sodium salted eggs coated with rice straw pulp. The Proceedings of 39 thKasetsart University Annual Conference. Kasetsart University, Bangkok, Thailand, 5–7 February 2001.

Yuwawutto, S., (1995). The development of processed soil for salted egg processing. Master of Science Thesis. Kasetsart University, Bangkok, Thailand.